Native oysters have been fished commercially off Whitstable, Kent in SE England since Roman times. Whitstable Bay is part of the Swale estuary, a shallow area with good tidal interaction between land and sea giving ideal conditions for good algal production and shellfish growth.

Seasalter Shellfish (Whitstable) Ltd owns two square miles of seabed off Whitstable known as the Pollard Ground. We also have a Crown fishery of similar size off the Isle of Sheppey called the Ham Ground. The grounds have been managed by “Seasalter” and it’s predecessors since 1853 when it was purchased from the Dean and Chapter of Canterbury Cathedral.

Traditionally the ground had provided fish for the Monastery larder since before Magna Carta in 1066. At the turn of the last century more than 100 boats and over 500 people were employed in harvesting and selling Whitstable Oysters.

In later years, however, oysters stocks and markets declined throughout the UK due to disease, bad winters, pollution from a nearby paper mill and over fishing. After World War Two, the industry as a whole became practically non existent.

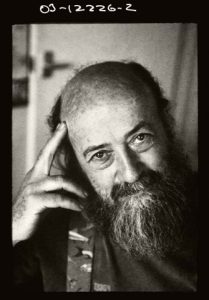

During the early sixties the Ministry of Agriculture and Fisheries began research on artificial breeding techniques for oysters using the Pacific oyster. A team of biologists led by a young John Bayes were employed by Associated Fisheries, (which took over the old Seasalter & Ham Oyster Fishery Company in 1965) to set up a hatchery at Whitstable and begin a re-stocking programme for both species. These were difficult times for oyster growers and many oyster fisheries ceased production. The specialist nature of artificial oyster rearing required high investment and extensive research.

The operation was under threat of closure until it was rescued in 1986 by John Bayes and renamed Seasalter Shellfish (Whitstable) Limited.

Seasalter Shellfish (Whitstable) Limited was based in the original Seasalter & Ham Oyster Fishery Company building at the East Quay of Whitstable Harbour until 2001 when the local council upped the rent and the premises became unviable. The lease was assigned to the Whitstable Oyster Company and Seasalter Shellfish moved to Reculver where the shellfish hatchery was based.

Until the summer of 2019, the company primarily operated from Reculver, eight miles East of Whitstable where the hatchery and several nursery systems were situated. An extensive pond system covering 8 hectares resulted in year round mollusc seed production including oyster and clam seed (Crassostrea gigas, Ostrea edulis, Mercenaria mercenaria, Tapes decussata, Tapes semi decussata) and other species of bivalve mollusc to order.

A completely different aspect of the business concerned the sale of technological advances developed by John Bayes and his team over the past three decades. “SeaCAP Systems” (Continuous harvest microalgal systems) and customised hatchery designs have been installed by John Bayes at both fish and shellfish farms in 16 countries and still run today as do many more copies of the original system.

John hung up his consultancy hat and travel bag in 2019 but is still leads the company and offers advice to growers when needed by email or telephone.

A combination of high overheads, production and water quality issues at Reculver meant the company made the painful decision to close the hatchery in 2019 and move entirely to Seasalter where the beach operation is based.

Over recent times, production has shifted towards the half grown seed market within the oyster farming industry. Over 30 million oysters are grown on trestles The Pollard Ground production site area is vast (some 12 km2) and there is a huge tidal flow through the Thames estuary passing constantly over the flats.

(photo copyright Brian Aris)